Installation Overview

Buildings made with Polycrete® ICFs offer many benefits compared to conventional methods. Also, the ease of installation of our ICF products combined with their performance make the Polycrete® choice an easy decision.

Let’s look at some key steps involved in all ICF installations. More details are available in our installation manuals.

FLEX 850 - Installation Manual FLEX 850 - Installation Manual

BIG BLOCK - Installation Manual BIG BLOCK - Installation Manual

Footing

The footing for an ICF building is similar to one for a conventional construction except that it must be robust enough to support the complete reinforced concrete structure. A key or other mechanical device should be used in the footing to prevent any lateral movement. Generally, vertical rebar is set into the footing where the walls will be, creating a link between the footing and the walls.

| |

|

| Footing | | First ICF course |

|

|

ICF installation

Even though Polycrete ICF installation is fast and easy, it is important to understand that installation and setup of the first ICF course is critical, as the other courses will rely on the first one. It is crucial to perfectly level the first ICF course in order to ensure perfect wall geometry for the succeeding courses. Remember that taking time to start well avoids losing time further on. The first course is installed using Polycrete® starting base for the corresponding wall thickness. While there are some slight differences in the installation of Polycrete ICF products (Flex 850 and Big Block), it is essentially the same approach. For instance, there are some basic rules to remember while installing Polycrete ICF such as maintaining a minimal overlap of ICF panels for good ICF wall stability. Generally, a 12” (30 cm) overlap is the minimal distance between two vertical joints.

|

| |

|

| Corner Guides | | Scaffolding system and wall bracing |

|

|

Squaring and leveling

The secret to ICF installation is to have everything level - horizontally and vertically. Some techniques and tools are available to help builders. For instance, corner guides (90° and 135°) are installed early to insure perfectly plumb corner alignment. The Polycrete scaffolding system is used to access upper ICF courses but also to help align the ICF walls prior to and after concrete pour.

|

|

Openings

Window and doors openings must be carefully prepared to allow easy installation of the doors and windows. The method consists of making a false buck that will either stay in place or will be removed after the concrete cures. This ‘false buck’ also serves as a formwork for the pouring of concrete and as a support for the final buck.

As for service openings (Water, gas, fuel lines, sanitary services, Chimney, Plumbing & Electrical, exhaust, and so on), EPS panels must be cut with a keyhole saw or a hot knife where the service penetration is to occur. Once the opening is cut, place an appropriate pipe or sleeve in the hole.

After pouring concrete, you’ll need to insulate (with polyurethane foam for example) and waterproof (with self adhesive waterproof membrane for example) all openings.

|

|

|

|

|

|

Concrete Pouring

Concrete placement shall be done in compliance with structural engineer’s specification and with all building code sand regulations. The properties of Polycrete® ICF’s expanded polystyrene ensure an optimum environment for curing concrete and minimizes concrete shrinkage. These insulating properties also allow you to pour concrete under low or high temperatures without impact on the quality of concrete wall.

The concrete pour must be performed with a boom pump that provides maximum control of the concrete flow to ensure the perfect placement in the ICF wall. The sturdiness of Polycrete® ICF allows installers to use a concrete vibrator to consolidate the concrete. Follow standard vibrator operation methods. Don’t forget that during the pouring of concrete, the lateral pressure exerted by the fresh concrete on the ICF structure can cause movement. In order to achieve a good result, it is mandatory to verify the proper alignment and the good verticality of the walls and immediately make all necessary adjustments.

|

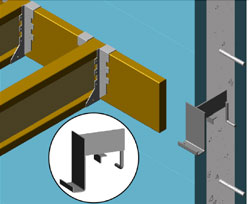

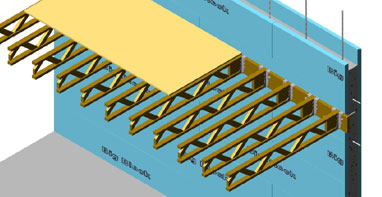

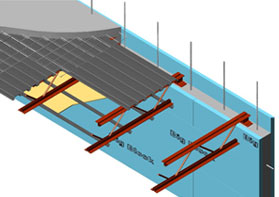

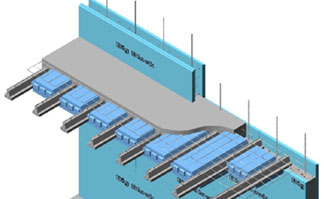

Floors

|

Floor connections with Polycrete® ICF walls are similar to floor connections to any standard concrete wall. Floor connections must be in accordance with structural engineering specifications. Floor anchors (slide in anchor, joist hanger or anchor bolt, or any other anchorage type) must be installed before or during the pouring of concrete. Several typical floor connections are shown below.

|

|

|

| Traditional wooden floor structure |

Polycrete® ICF ledger hanger |

|

|

| Floor of traditional wooden joists |

Concrete floor with steel joist and steel deck |

|

|

| Concrete Hourdi floor structure |

Polystyrene Hourdi floor structure |

|